info@gunther.co.uk

Multi-tip Solutions

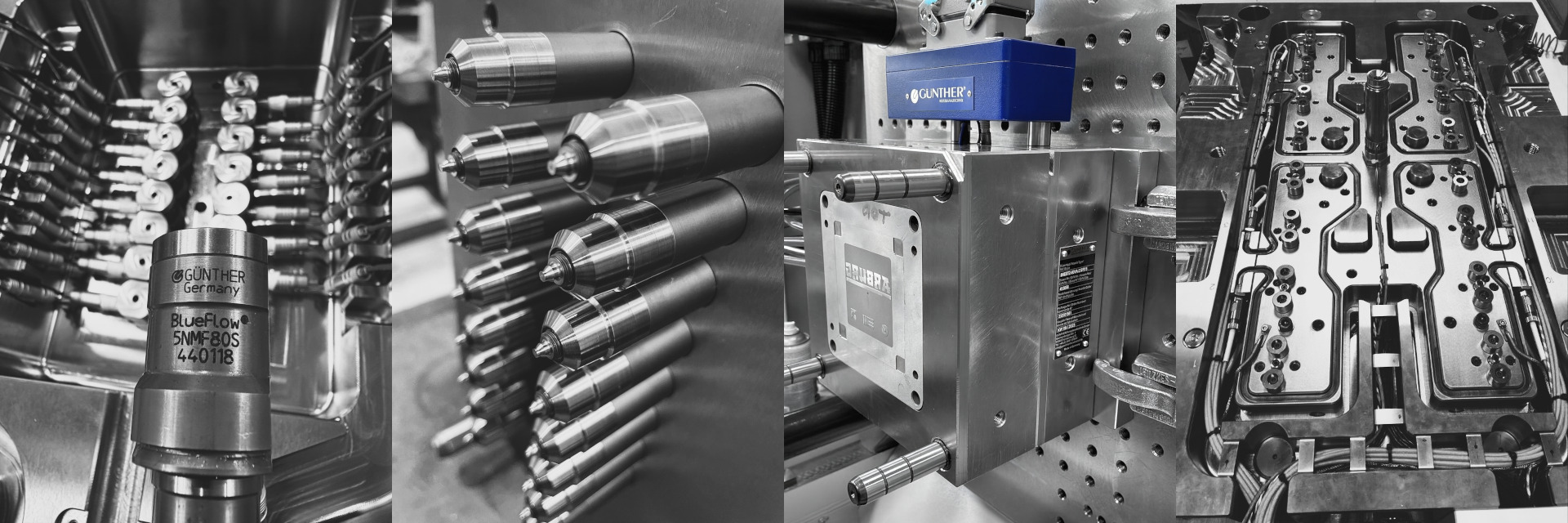

Günther multi-tip nozzles are engineered to deliver precision, flexibility, and consistency where conventional hot runner designs reach their limits. Whether producing small technical parts, medical or pharmaceutical components for low or high-cavity moulds or caps and closures, our multi-tip technology that offer solutions that ensure optimum part quality, reliability and productivity.

OktaFlow side-gate system with either a radial or linear layout enable up to eight perfectly balanced gates from a single nozzle body, providing compact, symmetrical flow paths and precise gate positioning — ideal for tight layouts and high-cavity tools.

Multi-Tip Nozzles

For applications needing multiple gates, our ClusterFlow nozzle system offers a clean, space-saving configuration with outstanding thermal balance and minimal residence time. Designed for components like medical well plates or very small parts 32 valve gates are possible on a footprint of only 35x70mm with nozzle centres of just 9mm. 96 or more cavities are possible with this design.

For ultra-compact multi-gate applications, the innovative Prisma nozzle with between 2-5 tips provides valve-gate centres from only 11 mm, enabling extremely close-pitch gating for miniature or densely packed components without compromising performance or serviceability. This design is especially suited for applications where concentricity is critical, geared components for example.

Beyond our standard designs, Günther engineers collaborate directly with customers to create tailored multi-tip solutions where required — adapting nozzle geometry, tip arrangement, and gating concepts to suit specific materials, part geometries, and mould requirements. From simple twin-gate setups to complex multi-cavity tools, our technology helps solve flow, balance, and surface-finish challenges with proven reliability.

Key benefits:

- Compact design for high-cavity or space-limited moulds

- Even temperature and flow balance across all gates

- Valve-gate centres from as little as 9mm (ClusterFlow) or 11 mm (Prisma)

- Customisable tip layouts and gating concepts

- Reduced cycle times and scrap rates

- Compatible with a wide range of engineering polymers

With Günther’s advanced multi-tip nozzle range — including OktaFlow, ClusterFlow, Prisma, and fully customised solutions — you gain the flexibility and performance to tackle even the most demanding moulding applications.

.jpg)

What our clients say

We’ve used Gunther Hot Runner Systems, OptiMach special machining, and Knarr collapsible cores via Gunther UK for a number of years. The quality is always exceptional and the service is responsive and reliable.

New Tooling Manager

Major UK OEM

Gunther’s demonstrated technical knowledge allow us to confidently provide working, robust moulds that produce consistent parts. Delivering a quality product and incredible support are more important today than ever before, Gunther never fails to deliver this, which in turn helps us to provide the same service to our customers. I can’t recommend them enough.

UK Toolmaker/moulder

We’ve been working with Gunther UK since 1988, and they’ve never let us down. The combination of personal service, trustworthy advice, and consistently high-quality hot runner systems and mould components has cemented our relationship over three decades. They feel less like a supplier and more like a partner we can rely on.

Gary Statham

Neptune Injection

Sign up for our newsletter

Newsletter