info@gunther.co.uk

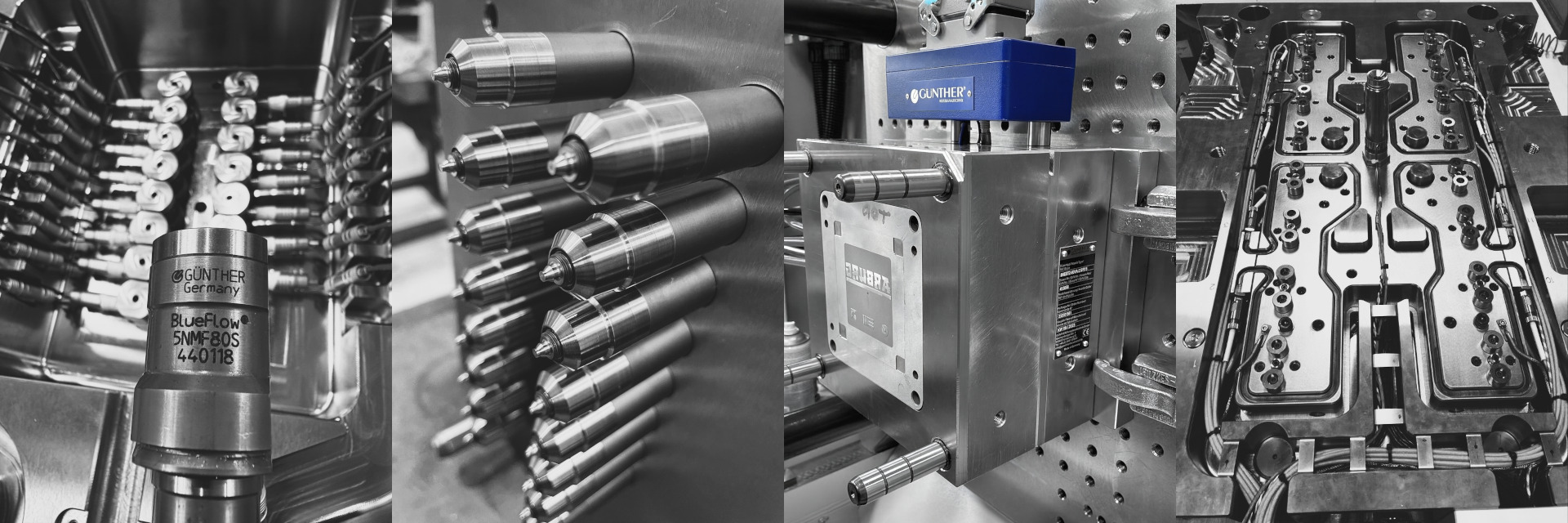

Valve Gate Nozzles

Gunther’s Valve Gate Systems are engineered for precision, efficiency, and durability, delivering consistent performance even in the most demanding moulding applications.

With designs tailored to your application, our valve gate systems provide controlled melt flow and precise cavity filling while maintaining uniform temperature. This ensures higher productivity, superior part quality, and reliable performance across a wide range of materials and applications.

Valve Gate Systems

At the heart of our innovation is Gunther’s patented bi-metallic titanium shaft technology, as seen in almost all our nozzles, which gives an extremely homogenous temperature profile.

In addition, our patented PM insert technology enhances nozzle performance by being, effectively, a replaceable gate insert to greatly improve mould maintenance. With the correct mould design, worn gates can be replaced without even removing the mould from the IMM.

Their ‘floating’ design means there is reduced thermal expansion for precise gate alignment and positioning.

Valve pins can further be individually adjusted so the best quality gate vestiges can be achieved.

Actuation is fully adaptable to your production needs. Gates can be operated via:

- Individual hydraulic, pneumatic cylinders or stepper motors for independent control

- Hydraulic or pneumatic synchro plates for synchronized gating

- Electric synchro plates for precise, programmable control

Gunther Valve Gate Systems also come with full after-sales support, ensuring smooth production from installation to ongoing operation. With a focus on quality, service, and innovation, our systems deliver reliable, high-performance solutions you can depend on.

What our clients say

We’ve used Gunther Hot Runner Systems, OptiMach special machining, and Knarr collapsible cores via Gunther UK for a number of years. The quality is always exceptional and the service is responsive and reliable.

New Tooling Manager

Major UK OEM

Gunther’s demonstrated technical knowledge allow us to confidently provide working, robust moulds that produce consistent parts. Delivering a quality product and incredible support are more important today than ever before, Gunther never fails to deliver this, which in turn helps us to provide the same service to our customers. I can’t recommend them enough.

UK Toolmaker/moulder

We’ve been working with Gunther UK since 1988, and they’ve never let us down. The combination of personal service, trustworthy advice, and consistently high-quality hot runner systems and mould components has cemented our relationship over three decades. They feel less like a supplier and more like a partner we can rely on.

Gary Statham

Neptune Injection

Sign up for our newsletter

Newsletter